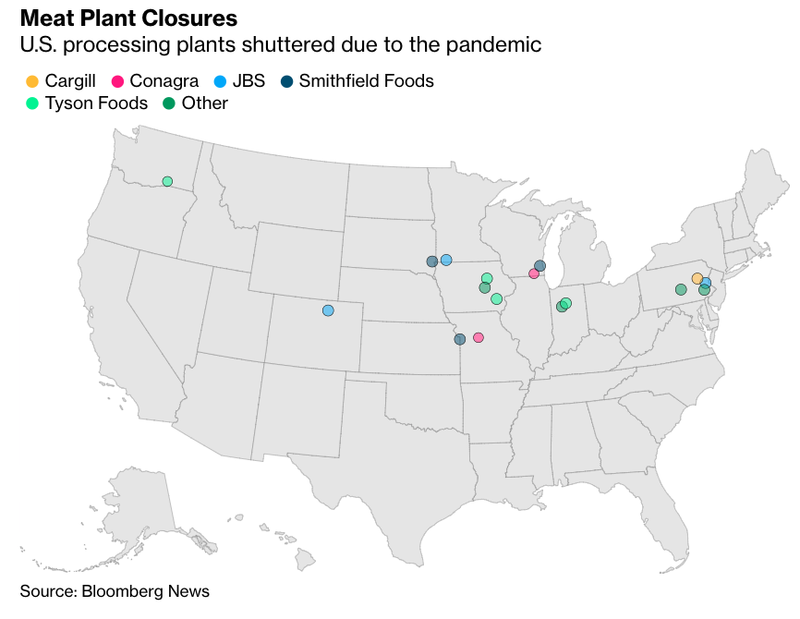

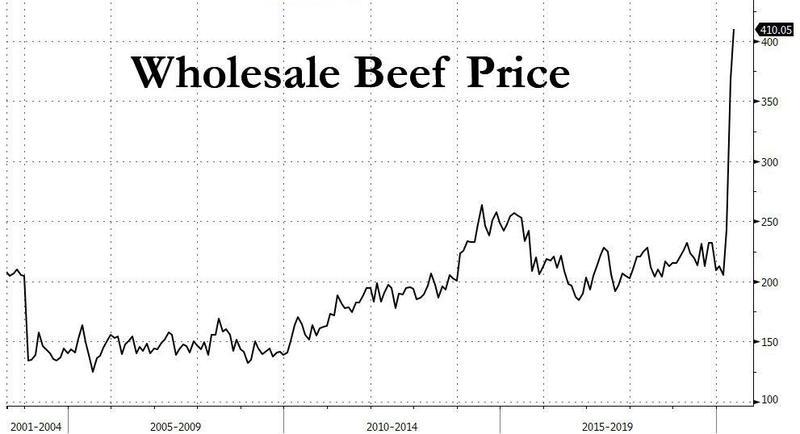

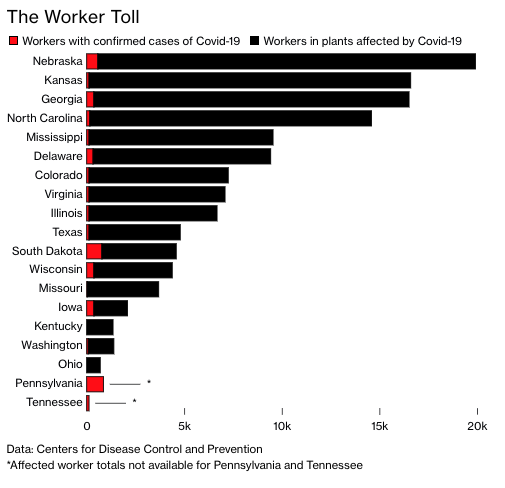

The latest update from the meatpacking crisis, otherwise known as “crisis in processing,” is that more than 5,000 workers, or about 1% of the entire industry, have contracted COVID-19, with at least 20 deaths. Outbreaks have been recorded at 115 meat and poultry plants, with 18 major operations shuttered. Industrywide, beef and pork production capacity collapsed 40% in April, triggering meat shortages in the first week of May, which have already been seen at some Kroger supermarkets and Wendy’s fast-food restaurants.

Will Sawyer, the lead economist at agricultural lender CoBank, expects meat shortages to persist through the end of the month. He said grocery stores are going to have 30% less meat with 20% higher prices seen over last year.

Americans got their first sour taste of a meat shortage when Tyson Foods Inc., the largest US processor, took out a full-page ad in the New York Times in late April to warn the country: the “food supply chain is breaking.”

Bloomberg sums up why meat processing plants have become a breeding ground for the virus:

“The cold, damp conditions and crowded workstations in meatpacking plants make infectious diseases particularly hard to control. But not impossible. In Europe, where labor protections are stronger and most plants are smaller and more automated than in the U.S., the industry has avoided disabling outbreaks.”

One glance inside a plant and it becomes increasingly evident why this virus spreads like wildfire.

On March 25, Cargill worker Rafael Benjamin was ordered by a supervisor to remove his mask because it was creating unnecessary fears among plant employees.

Benjamin was admitted to the ICU and put on a ventilator weeks later. He died on April 19 https://t.co/Ty6TFqXDWd pic.twitter.com/AcfwNfDFTi

— Businessweek (@BW) May 7, 2020

Remember the shocking coronavirus cough simulation inside a supermarket? Well, just imagine that inside a processing plant…

And it’s not just the horrid conditions, Bloomberg notes when the virus was unfolding, JBS-USA, the world’s largest meat producer, tried to cover up the virus outbreak at one facility in Texas. The company neglected to tell workers about others getting sick, resulting in at least one person dead.

At JBS-USA’s beef plant in the Texas Panhandle town of Cactus, the company didn’t inform its 3,000 employees that a co-worker had gone home sick with suspected symptoms until nine days later, when the test for Covid-19 came back positive, according to three plant employees. By that time, multiple workers were falling sick, yet for at least a week longer, managers continued to deny the plant had a serious outbreak and told sick workers not to discuss their diagnoses.

On April 5 the wife of Anthony Germain fell ill with a fever, he says. (Germain, who doesn’t work for JBS, insisted on anonymity for his wife to protect her and other family members from losing their jobs at the plant.) She was still vomiting a few days later, but her fever was gone, so a JBS nurse told her to come back to work, he says. She tested positive for the virus on April 10. A plant superintendent followed up with a phone call and instructed Germain’s wife not to tell anyone she had Covid-19, according to Germain, who says he listened to the call and was outraged by the breach of pandemic protocol.

“Hell no, I’m not keeping my mouth shut,” he says. “They don’t want to cause fear and panic in the plant, but that’s already there. This is something that should not be kept in the dark.” Nikki Richardson, a JBS spokeswoman, says no employee is asked to keep quiet about having Covid-19 and JBS informs workers when one tests positive. Employees with virus symptoms are sent home and no one is pressured to work sick, she says.