by TYLER DURDEN

No sooner did we write about the fact that the ports of LA and Long Beach still won’t work round-the-clock shifts despite a massive backlog than the Port of Los Angeles is said to have asked for more federal funding.

So far, the government has invested about $11 billion in the eastern Gulf coast compared to just $1 billion on the West Coast, the head of the Port of Los Angeles, Gene Seroka, told Bloomberg this week.

Seroka said that truck capacity has also slowed down the port, with 50% of registered truck drivers calling to the port at least once a week and 30% of truck appointments going unused every day.

Heading into the holiday season, Seroka said he thinks many retailers have pulled forward inventory and will manage well: “I feel confident the retail community will rise to the occasion.”

Jim Monkmeyer, the president of transportation for Deutsche Post AG’s DHL Supply Chain unit also told Bloomberg this week that the logistics markets will see “ups and downs for the next year, at least.”

Recall, we wrote yesterday that despite the shortages, the busiest U.S. port still shuts down for hours on most days and is closed on Sundays. “Tens of thousands” of containers remain stuck at the ports of Los Angeles and Long Beach. More than 60 ships are lined up to dock, we noted.

More than 25% of all American imports pass through one of the two ports. LA and Long Beach collectively manage 13 private container terminals. Long Beach officials finally said last week they would try operating 24 hours a day between Monday and Thursday. LA says it’s going to keep existing hours and wait for the rest of the supply chain to extend their hours first.

Seroka had previously said: “It has been nearly impossible to get everyone on the same page towards 24/7 operations.”

Ports in places like Asia and Europe, for contrast, have operated around the clock “for years”, the report notes.

Uffe Ostergaard, president of the North America region for German boxship operator Hapag-Lloyd AG said: “With the current work schedule you have two big ports operating at 60%-70% of their capacity. That’s a huge operational disadvantage.”

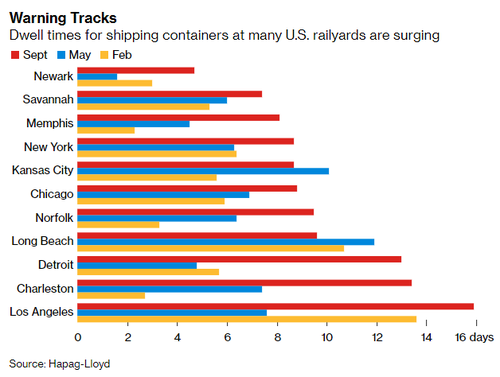

As the shortage continues, all members of the supply chain including truckers, warehouse operators and railways, are blaming each other for the shortages of products. All parts of the supply chain are also struggling with a shortage of labor.

A longshore shift at either of the two ports used to be either 8AM to 4PM or 6PM to 3AM. Overnight shifts of 5 hours were “rarely used” because they are up to 50% more expensive, the report says.

The International Longshore and Warehouse Union says their members will work a third shift, but only after the pileup of containers is fetched out of the port so there is space.

Frank Ponce De Leon, a coast committeeman at the ILWU, said: “Congestion won’t be fixed until everyone steps up and does their part. The terminal operators have been underutilizing their option to hire us for the third shift.

Matt Schrap, chief executive of the Harbor Trucking Association, added: “There is too much congestion from empty containers on terminals. The shipping lines aren’t moving the boxes out, which is preventing us from returning empties that we are storing in our yards.”

Mario Cordero, executive director at the Port of Long Beach concluded: “It’s impossible to effectively move such volumes if we don’t move to 24/7 operations across the supply chain. They do it in other parts of the world.”