by TYLER DURDEN

Just-in-time (JIT) is a production model used by companies to create items for immediate demand. The point of JIT is to avoid the waste associated with overproduction. But when supply chain snarls appear, JIT has become a significant headache for US companies such as Ford who has had to shutter multiple vehicle plants because of their inability to source semiconductor chips.

Companies are rethinking their production model to just-in-case inventory (JICI), a more suitable model in today’s challenging environment that allows more inventory to be stored and will help ensure future orders are filled.

JIT still dominates the corporate world, but JICI could make a strong comeback due to global uncertainties. Bloomberg has provided an in-depth view of various US industries and their potential disruptions in foreign supplies.

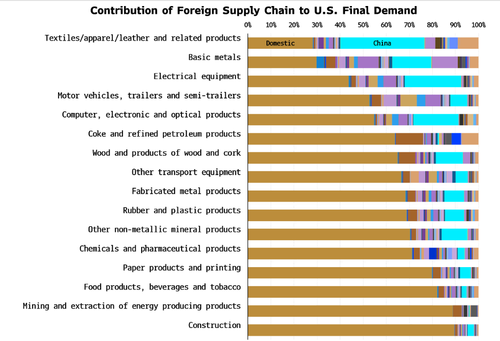

Foreign supply-chain production is the largest in textiles, basic metals, electrical equipment, motor vehicles, and electronics. Many of these industries are entirely reliant on production from China. The problem with that is Beijing has ordered energy-intensive factories to shutter operations to conserve electricity amid a massive energy crunch. This will complicate the picture for firms that source a majority of their goods from the country. On top of this all, port congestion on either side of the Pacific continues to increase to record levels.

JIT is a flawed production model when supply chains break. Maybe companies will learn to transition to JICI and hold inventory in case of a rainy day.

For more insight on when global supply chain bottlenecks will subside, Dubai’s DP World, one of the biggest international port operators, Chairman and CEO Sultan Ahmed Bin Sulayem told Bloomberg earlier this month that disruptions could last for another two years.

“The global supply chain was in crisis at the beginning of the pandemic,” Bin Sulayem said. “Maybe in 2023 we’ll see an easing.”

So the complex, interconnectedness of the global supply chain combined with JIT is a recipe for disaster in today’s brave new world. This suggests that more US corporates could embrace JICI and diversify their supply chains away from China to mitigate risk.